Your Tumble Dryer Won't Stop

Is your tumble dryer taking longer than normal to complete a drying cycle, or perhaps failing to stop at all even? Here we describe the possible causes in detail to help you understand and get to the bottom of the problem.

THE POTENTIAL CAUSES FOR THIS FAULT:

-

There is a problem with the electrical installation

-

Your clothes have not been spun enough

-

The tumble dryer has been placed in an unsuitable location

-

The lint filter is clogged

-

The condenser is blocked

-

The wrong programme has been selected

-

The heating element is faulty

-

The bearing is worn

-

The lambda sensor is faulty

-

The temperature sensor is faulty

-

The programmer is damaged

-

The main circuit board (PCB) is faulty

WARNING

Before you do anything to your appliance, make sure you disconnect it from the power supply.

There is a risk of electric shock.

Wear suitable protective gloves if you need to dismantle anything.

There is a risk of getting cut or injured

There is a problem with the electrical installation

The electricity installation enables your tumble dryer to function and operate. It could actually be that the problem you're experiencing is due to an issue with the supply to your plug socket. This needs to be receiving 230 volts and must be correctly earthed. If the socket is also being used by other appliances, the tumble dryer will struggle to dry your clothes and could break down and stop operating. Check the socket is definitely working by, for example, plugging a different appliance into it.

The electricity installation enables your tumble dryer to function and operate. It could actually be that the problem you're experiencing is due to an issue with the supply to your plug socket. This needs to be receiving 230 volts and must be correctly earthed. If the socket is also being used by other appliances, the tumble dryer will struggle to dry your clothes and could break down and stop operating. Check the socket is definitely working by, for example, plugging a different appliance into it.

Quick reminder: you are strongly advised not to plug large domestic appliances into multi-socket extension leads. Large domestic appliances should be allocated their own dedicated wall socket.

Your clothes have not been spun enough

If you haven't sufficiently spun your clothes before putting them in the tumble dryer, this will automatically extend the time they take to dry. Always ensure you first spin your clothes at a speed of at least 800 rpm, otherwise your tumble dryer will take longer to dry them.

If you haven't sufficiently spun your clothes before putting them in the tumble dryer, this will automatically extend the time they take to dry. Always ensure you first spin your clothes at a speed of at least 800 rpm, otherwise your tumble dryer will take longer to dry them.

The tumble dryer has been placed in an unsuitable location

It is essential to choose a cool, well-aired location for your tumble dryer. Your appliance will not work as efficiently if it's placed in a room that's too cold or too hot. Additionally, and because your tumble dryer draws in cool air from the front, nothing should ever be placed in front of it. If there is anything obstructing your appliance, it will struggle to get clothes dry and will take longer to complete its cycle.

It is essential to choose a cool, well-aired location for your tumble dryer. Your appliance will not work as efficiently if it's placed in a room that's too cold or too hot. Additionally, and because your tumble dryer draws in cool air from the front, nothing should ever be placed in front of it. If there is anything obstructing your appliance, it will struggle to get clothes dry and will take longer to complete its cycle.

The lint filter is clogged

The lint filter prevents fibres from circulating around inside your tumble dryer's air channels. It will normally be located at the bottom of the door opening. If it's not cleaned after every use, your appliance may have problems working. Because the air won't be able to pass through the blocked filter easily, the drying time will be extended.

The lint filter prevents fibres from circulating around inside your tumble dryer's air channels. It will normally be located at the bottom of the door opening. If it's not cleaned after every use, your appliance may have problems working. Because the air won't be able to pass through the blocked filter easily, the drying time will be extended.

Purchase a lint filter for your Tumble Dryer

The condenser is blocked

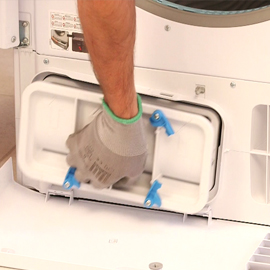

Condensers are found only on condenser tumble dryers. They enable the appliance to produce condensation and convert it to water. If the condenser is blocked by dirt or fibres, the air will no longer be able to circulate properly and the appliance will struggle to dry your clothes, thus extending the time it takes to complete its cycle. We recommend you clean the condenser at least once or twice per month.

Condensers are found only on condenser tumble dryers. They enable the appliance to produce condensation and convert it to water. If the condenser is blocked by dirt or fibres, the air will no longer be able to circulate properly and the appliance will struggle to dry your clothes, thus extending the time it takes to complete its cycle. We recommend you clean the condenser at least once or twice per month.

Purchase a condenser for your Tumble Dryer

The wrong programme has been selected

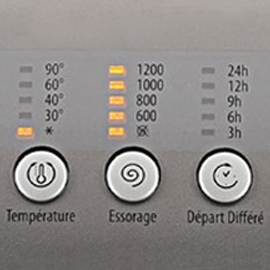

Your tumble dryer may be taking longer to complete its drying cycle due to the wrong programme being selected. If the 'delay start' function has been activated, for example, this will prevent the drying cycle from starting until a certain period of time has elapsed. Choosing a synthetics programme when you actually want to dry cotton items will also cause the drying time to increase. Additionally, the 'anti-crease' function, if selected, will cause the drum to continue to move occasionally after the cycle has finished, and this will continue indefinitely. Carefully read through your appliance's user manual to find out which programme and options to use.

Your tumble dryer may be taking longer to complete its drying cycle due to the wrong programme being selected. If the 'delay start' function has been activated, for example, this will prevent the drying cycle from starting until a certain period of time has elapsed. Choosing a synthetics programme when you actually want to dry cotton items will also cause the drying time to increase. Additionally, the 'anti-crease' function, if selected, will cause the drum to continue to move occasionally after the cycle has finished, and this will continue indefinitely. Carefully read through your appliance's user manual to find out which programme and options to use.

The heating element is faulty

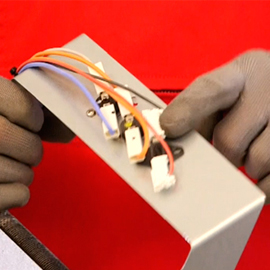

The heating element assembly heats the air that circulates inside your tumble dryer. It will normally be located on your appliance's back panel, behind the drum. If one of the individual elements has failed, your tumble dryer will not be able to heat up sufficiently and will therefore take longer to dry. You can check these heating elements yourself by looking to see whether the filaments (the spring-like parts) are broken. You can also test them for continuity using a multimeter in ohmmeter mode. Unplug the appliance from the electricity mains and locate the heating element you want to check. Disconnect all the connectors and place the meter's two probes on the element's terminals. If you don't get a value, the element will need to be replaced.

The heating element assembly heats the air that circulates inside your tumble dryer. It will normally be located on your appliance's back panel, behind the drum. If one of the individual elements has failed, your tumble dryer will not be able to heat up sufficiently and will therefore take longer to dry. You can check these heating elements yourself by looking to see whether the filaments (the spring-like parts) are broken. You can also test them for continuity using a multimeter in ohmmeter mode. Unplug the appliance from the electricity mains and locate the heating element you want to check. Disconnect all the connectors and place the meter's two probes on the element's terminals. If you don't get a value, the element will need to be replaced.

Purchase a heating element for your Tumble Dryer

The bearing is worn

If your tumble dryer is the type that automatically calculates the drying time, it's possible the drum shaft or the bearing is damaged or fouled up and this is preventing the sensor that determines whether your clothes are dry from functioning properly. If your appliance does not seem to be detecting when your clothes are dry any more and is taking longer than normal to complete its cycle, it's probably worth checking the condition of these components and, if necessary, either cleaning them or replacing them.

If your tumble dryer is the type that automatically calculates the drying time, it's possible the drum shaft or the bearing is damaged or fouled up and this is preventing the sensor that determines whether your clothes are dry from functioning properly. If your appliance does not seem to be detecting when your clothes are dry any more and is taking longer than normal to complete its cycle, it's probably worth checking the condition of these components and, if necessary, either cleaning them or replacing them.

Purchase bearings for your Tumble Dryer

The lambda sensor is faulty

Tumble dryers that automatically calculate the drying time have a small sensor (in the form of a metal strip) inside the filter holder at the front of the appliance. If this sensor or its wires get damaged and, for example, end up coming into contact with the appliance's metal casing, the tumble dryer will continue drying indefinitely, without coming to a stop. We therefore advise you to check the condition of the sensor. If necessary, clean the metal strips with white vinegar to improve the quality of the contact they make with the clothes.

Tumble dryers that automatically calculate the drying time have a small sensor (in the form of a metal strip) inside the filter holder at the front of the appliance. If this sensor or its wires get damaged and, for example, end up coming into contact with the appliance's metal casing, the tumble dryer will continue drying indefinitely, without coming to a stop. We therefore advise you to check the condition of the sensor. If necessary, clean the metal strips with white vinegar to improve the quality of the contact they make with the clothes.

The temperature sensor is faulty

The temperature sensor enables your tumble dryer to measure both its internal temperature and that of its heating element. There are normally two of these sensors inside the appliance. If one of them is faulty, it will provide an inaccurate temperature value, which will prevent the appliance from bringing its drying cycle to an end. You can check the sensors using a multimeter in ohmmeter mode. Unplug your appliance from the electricity mains and find where the sensors are located. Normally, one will be located in the front air channel and the other will be near the heating element at the back of the appliance. Next, disconnect all the connectors from the sensor and place the meter's two probes on its two terminals to check it definitely has continuity. The sensor must have open continuity: the multimeter should display a value in ohms. You can find out what the correct value should be by contacting our technical service or the manufacturer's after-sales service.

The temperature sensor enables your tumble dryer to measure both its internal temperature and that of its heating element. There are normally two of these sensors inside the appliance. If one of them is faulty, it will provide an inaccurate temperature value, which will prevent the appliance from bringing its drying cycle to an end. You can check the sensors using a multimeter in ohmmeter mode. Unplug your appliance from the electricity mains and find where the sensors are located. Normally, one will be located in the front air channel and the other will be near the heating element at the back of the appliance. Next, disconnect all the connectors from the sensor and place the meter's two probes on its two terminals to check it definitely has continuity. The sensor must have open continuity: the multimeter should display a value in ohms. You can find out what the correct value should be by contacting our technical service or the manufacturer's after-sales service.

The programmer is damaged

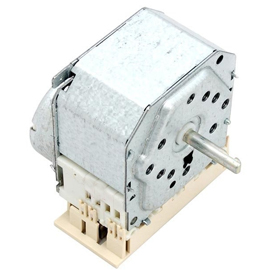

If your appliance is fitted with a mechanical-type programmer, this will contain gears and cams, and these cams act by pressing on electrical contacts. If the contacts are damaged, your tumble dryer won't be able to operate, in which case you'll need to replace the programmer.

If your appliance is fitted with a mechanical-type programmer, this will contain gears and cams, and these cams act by pressing on electrical contacts. If the contacts are damaged, your tumble dryer won't be able to operate, in which case you'll need to replace the programmer.

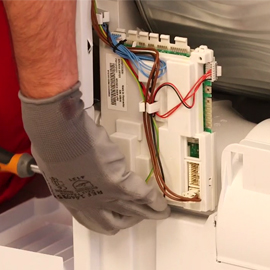

The main circuit board (PCB) is faulty

The circuit board manages all your tumble dryer's functions (i.e. motor, heating, etc.). If everything else detailed above has been checked, it may be that the circuit board needs replacing. You can either do this yourself or call on the services of a manufacturer-approved engineer.

The circuit board manages all your tumble dryer's functions (i.e. motor, heating, etc.). If everything else detailed above has been checked, it may be that the circuit board needs replacing. You can either do this yourself or call on the services of a manufacturer-approved engineer.